Understanding the intricacies of industrial automation often involves deciphering technical documentation. The 1756 Irt8i wiring diagram is a crucial piece of information for anyone working with Rockwell Automation's ControlLogix systems, specifically when integrating the 1756-IRT8I temperature input module. This diagram serves as a blueprint, guiding installers, maintenance personnel, and engineers through the correct connections for reliable operation.

Understanding the 1756 Irt8i Wiring Diagram

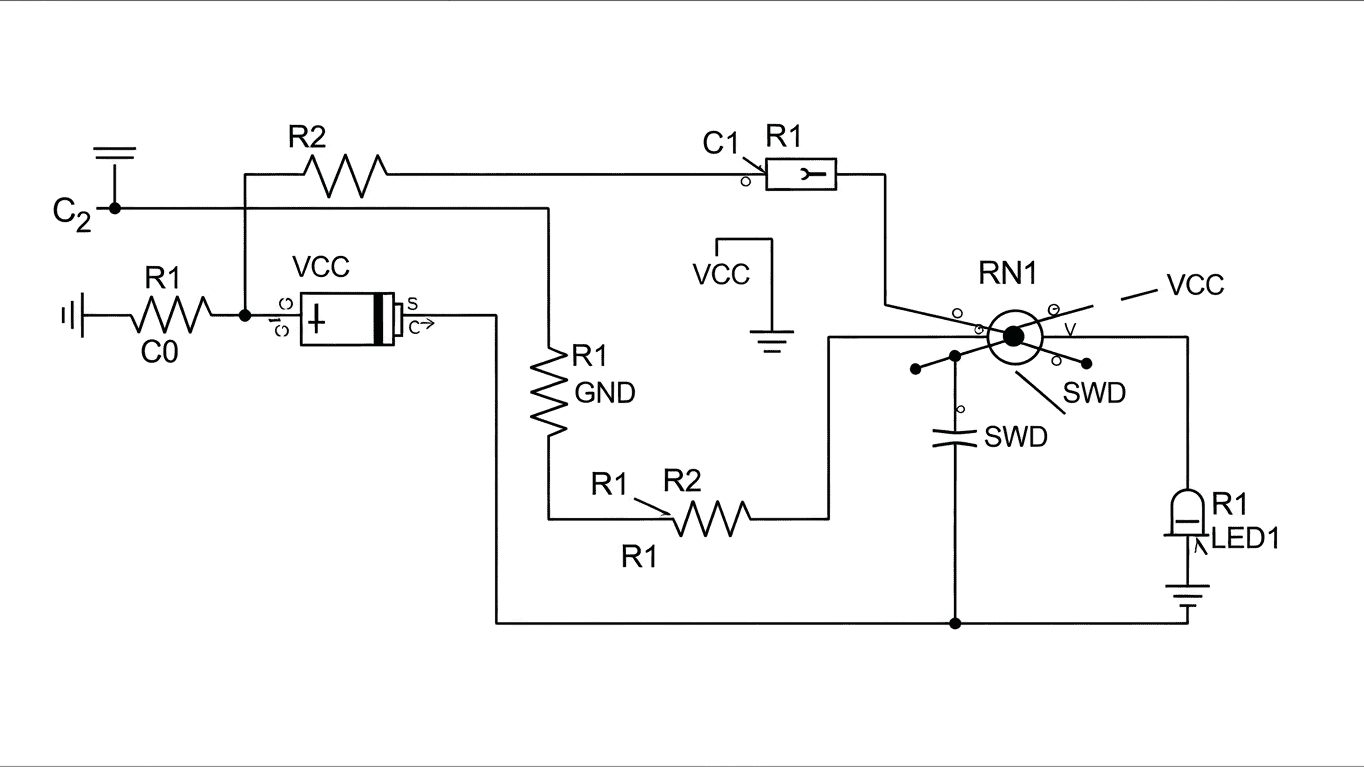

The 1756-IRT8i wiring diagram is a schematic that illustrates the electrical connections required for the Allen-Bradley ControlLogix 1756-IRT8I temperature input module. This module is designed to interface with various types of temperature sensors, such as thermocouples and RTDs, and convert their signals into digital data that a PLC can process. The diagram details how to connect the sensor inputs, power supply, and communication lines to the module, ensuring proper functionality within the larger automation system. The accuracy of these connections is paramount for the correct measurement and control of temperature in industrial processes.

There are several key components and considerations highlighted in a typical 1756 Irt8i wiring diagram:

- Input terminals for thermocouples (Type J, K, T, E, R, S, B, N) and RTDs (Pt100, Pt1000, Ni120, etc.).

- Screw terminals for connecting sensor wires.

- Power input terminals for the module's own power supply.

- Potential connections for external cold junction compensation.

- Grounding points for noise reduction and safety.

The 1756 Irt8i wiring diagram is not just a visual aid; it's a critical procedural guide. It dictates the physical wiring sequence, helping to avoid common mistakes. For instance, a diagram might specify:

- The correct polarity for sensor connections.

- The gauge of wire to be used for different signal types.

- The location of shielding for noise-sensitive signals.

- The proper configuration for 2-wire, 3-wire, or 4-wire RTD measurements.

To ensure your 1756-IRT8I module is installed and connected correctly, always consult the official documentation provided with your specific module. This information is invaluable for achieving seamless integration and optimal performance.