Understanding an 18-pulse VFD wiring diagram is key to successfully integrating this advanced motor control technology into your systems. An 18-pulse VFD wiring diagram details the connections required to harness the benefits of an 18-pulse variable frequency drive (VFD), which significantly reduces harmonic distortion compared to standard VFDs.

What is an 18-pulse VFD Wiring Diagram?

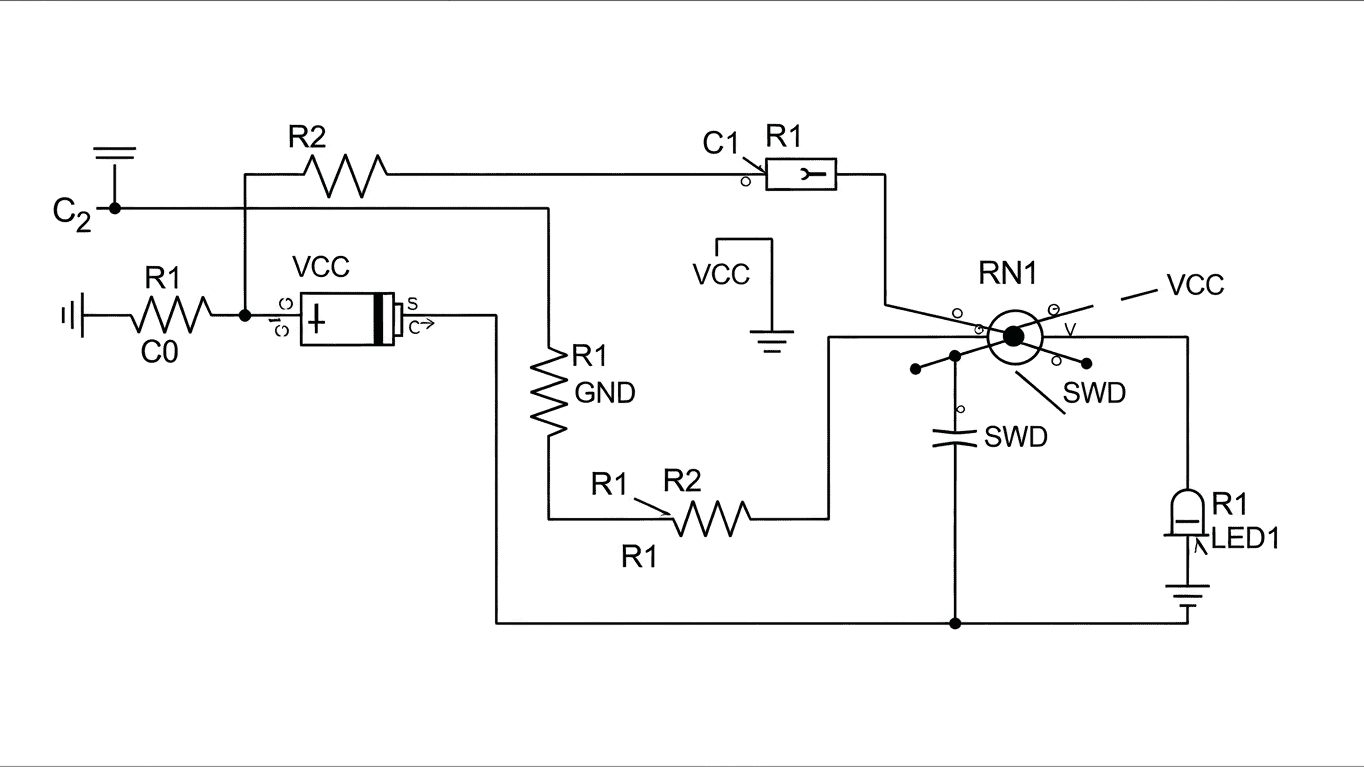

An 18-pulse VFD wiring diagram illustrates how to connect an 18-pulse variable frequency drive to a power source and a motor. These drives are designed to operate on standard AC power and control the speed of AC induction motors. The "18-pulse" designation refers to the number of output pulses the VFD uses to create its simulated AC waveform for the motor. This sophisticated pulsing technique is the core of what makes these VFDs more efficient and less disruptive to the power grid.

The primary advantage of an 18-pulse VFD lies in its ability to dramatically reduce harmonic currents. Standard VFDs, often 6-pulse or 12-pulse, can inject significant harmonic distortion back into the power supply. This distortion can cause issues like overheating of transformers, interference with sensitive electronic equipment, and reduced power factor. An 18-pulse VFD minimizes these problems through a complex internal rectification and transformer arrangement. To achieve this, the wiring diagram will often show:

- Multiple input phases for rectification.

- Specialized input transformers to shift phase angles.

- The connection points for the motor and the AC power source.

The importance of proper wiring for an 18-pulse VFD cannot be overstated, as incorrect connections can lead to reduced performance, damage to the equipment, or safety hazards.

The setup often involves more components than a basic VFD. Here’s a general overview of what you might find in an 18-pulse VFD wiring diagram:

- AC Power Input: This shows the connection to the main AC power supply, which is typically a three-phase source.

- Input Transformers: A key feature of 18-pulse systems is the use of specific input transformers. These transformers are designed to create phase shifts in the incoming power, which is crucial for the 18-pulse rectification process. The diagram will detail how these transformers are interconnected.

- Rectifier Section: The incoming, phase-shifted AC power is then fed into a rectifier. In an 18-pulse system, this is a more complex arrangement than a standard VFD, often involving multiple rectifier stages.

- DC Bus: The rectified DC voltage is smoothed and filtered in a DC bus.

- Inverter Section: This section converts the DC power back into a variable frequency, variable voltage AC output to control the motor.

- Motor Connections: The final output terminals are clearly marked for connecting to the motor windings.

Consider this simplified table illustrating the difference in harmonic reduction:

| VFD Type | Typical Harmonic Distortion Reduction |

|---|---|

| 6-pulse VFD | Moderate |

| 12-pulse VFD | Significant |

| 18-pulse VFD | Very High |

By carefully following the 18-pulse VFD wiring diagram, engineers and technicians can ensure that the VFD is installed correctly, maximizing its harmonic reduction benefits and ensuring reliable operation. Always refer to the manufacturer's specific wiring diagram for your model to guarantee a safe and effective installation.

For precise and detailed instructions tailored to your specific 18-pulse VFD model, please consult the comprehensive documentation and wiring schematics provided by the drive's manufacturer. This ensures optimal performance and safety.