The 1794-OA16 wiring diagram is a crucial document for anyone working with Allen-Bradley ControlLogix or MicroLogix systems, specifically concerning the 1794-OA16 output module. Understanding this diagram is key to successfully integrating, troubleshooting, and maintaining your industrial automation equipment. This guide will demystify the 1794-OA16 wiring diagram, providing you with the knowledge you need.

Understanding the 1794-OA16 Wiring Diagram and Its Application

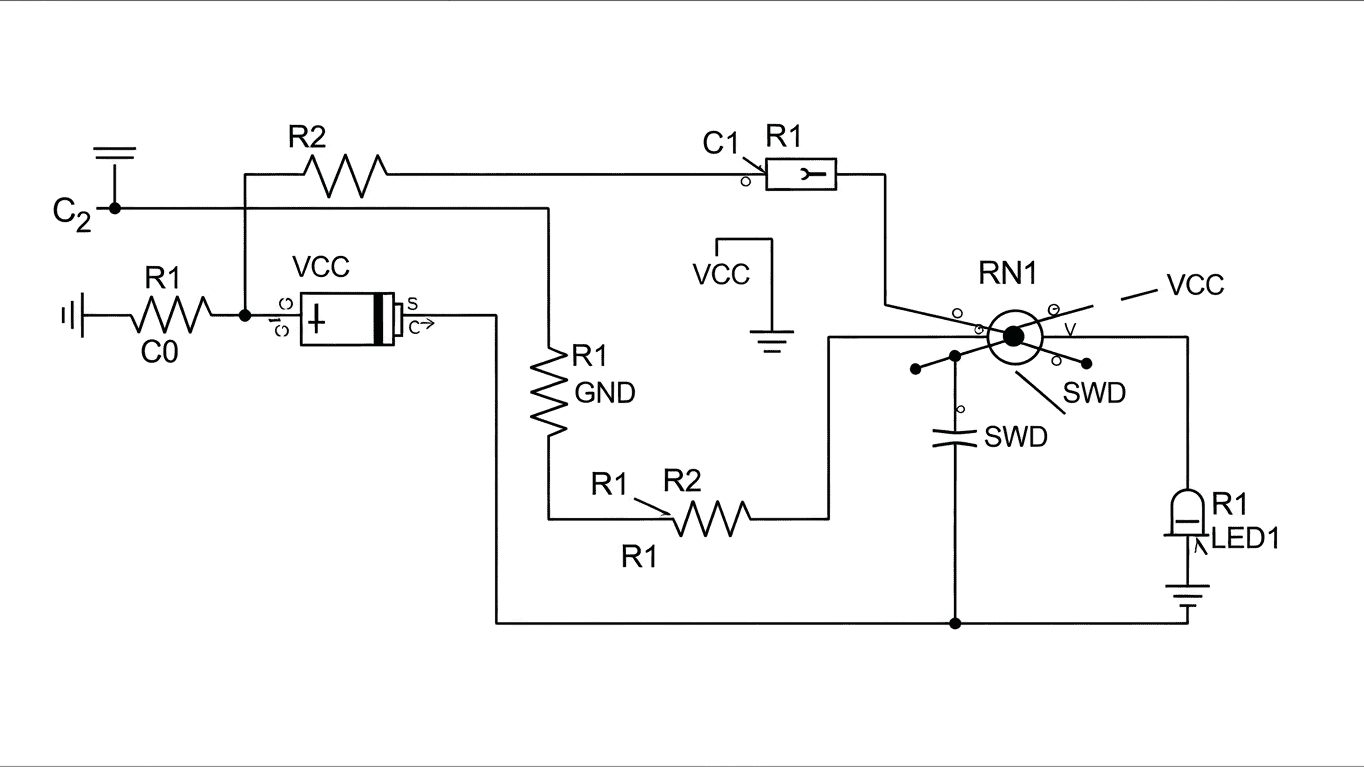

The 1794-OA16 is a sixteen-point analog output module designed for industrial control applications. Its primary function is to translate digital signals from a programmable logic controller (PLC) into analog electrical signals that can control devices like variable speed drives, proportional valves, or other actuators. The 1794-OA16 wiring diagram serves as the blueprint for physically connecting this module to the PLC and the external devices it controls. It details the terminal assignments, voltage and current requirements, and the specific wiring configurations needed for proper operation. Without the 1794-OA16 wiring diagram, accurately installing and commissioning this module would be a complex and error-prone task.

These diagrams are indispensable for several reasons. Technicians and engineers rely on them to ensure safe and correct wiring practices. They prevent common mistakes like incorrect polarity or exceeding voltage limits, which could damage the module or other connected equipment. The 1794-OA16 wiring diagram outlines:

- Terminal mapping: Clearly shows which terminal is designated for each of the 16 analog outputs.

- Power and ground connections: Specifies where to connect the necessary power supply and grounding.

- Signal lines: Identifies the conductors that carry the actual analog output signals.

- Configuration options: Sometimes, diagrams might hint at or refer to documentation for specific configuration jumpers or DIP switches.

The importance of following the 1794-OA16 wiring diagram precisely cannot be overstated , as it directly impacts the reliability and performance of the entire automation system. For example, consider a scenario where you need to connect multiple output modules. The diagram helps to:

- Identify the common power and ground rails.

- Distinguish between different output types (e.g., voltage vs. current outputs, though the OA16 is typically configurable).

- Ensure proper termination of each signal wire to its corresponding output point on the module.

When planning a new installation or modifying an existing one, the 1794-OA16 wiring diagram is the first reference. It aids in calculating cable lengths, selecting appropriate wire gauges, and understanding the physical layout of the control panel. Here is a simplified representation of how output terminals might be organized on the module, as depicted in a typical diagram:

| Terminal Block | Output Point | Function |

|---|---|---|

| 1 | 0 | Analog Output 0 |

| 2 | 1 | Analog Output 1 |

| ... | ... | ... |

| 16 | 15 | Analog Output 15 |

To ensure you have the most accurate and detailed information for your specific 1794-OA16 module, please refer to the official documentation provided by Rockwell Automation. This documentation contains the definitive 1794-OA16 wiring diagram and other essential specifications.