Navigating the intricacies of industrial automation can often feel like deciphering a secret language. The 1794-OE12 wiring diagram is a critical document for anyone working with Allen-Bradley's Flex I/O modules, specifically the 1794-OE12 analog output module. Understanding this diagram is not just helpful; it's essential for proper installation, troubleshooting, and ensuring the safe and efficient operation of your control systems. This article will guide you through the key aspects of the 1794-OE12 wiring diagram.

The Foundation of 1794-OE12 Connectivity

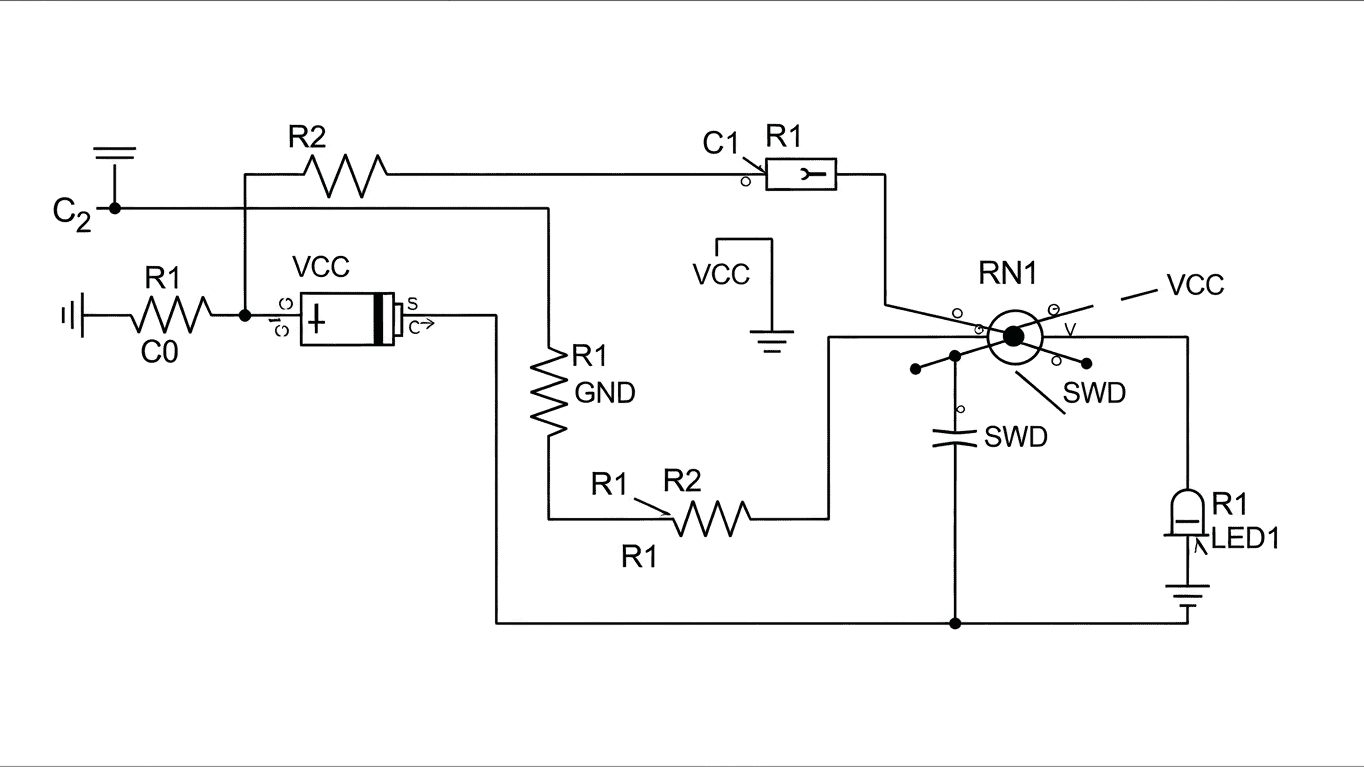

The 1794-OE12 wiring diagram is essentially a visual blueprint that details how to connect the 1794-OE12 analog output module to the rest of your control system. This module is designed to take digital signals from a programmable logic controller (PLC) and convert them into analog voltage or current signals that can control devices like variable frequency drives (VFDs), proportional valves, or indicators. The wiring diagram provides precise information on terminal assignments, power requirements, and signal routing. This diagram is the single most important document for ensuring correct and safe electrical connections.

When you examine the 1794-OE12 wiring diagram, you'll typically find:

- Terminal block layout: Showing the physical arrangement of connection points.

- Power connections: Indicating where to connect the DC power supply for the module and its associated circuitry.

- Analog output terminals: Clearly labeling the terminals for each of the module's four analog outputs.

- Signal ground connections: Delineating the common ground points for the analog signals.

- Internal jumper configurations (if applicable): Although the 1794-OE12 is largely configured via software, some diagrams might illustrate jumper settings for specific operational modes or voltage/current selection.

The information presented in the 1794-OE12 wiring diagram is crucial for several reasons. For new installations, it guarantees that the module is wired according to the manufacturer's specifications, preventing potential damage to the module, the PLC, or connected field devices. During maintenance or upgrades, the diagram serves as a quick reference to isolate issues or confirm existing connections. A typical wiring scenario might involve connecting the module's power terminals to a 24 VDC power source, then routing the individual analog output signals to the control inputs of external devices. The diagram will detail which terminal on the 1794-OE12 corresponds to each specific output. For example, a common layout might be:

| Module Terminal | Function |

|---|---|

| V+ | DC Power Input |

| 0V | DC Power Return/Ground |

| 1+ | Analog Output 1 (Positive/Hot) |

| 1- | Analog Output 1 (Negative/Common) |

| 2+ | Analog Output 2 (Positive/Hot) |

| 2- | Analog Output 2 (Negative/Common) |

For accurate and reliable implementation of your 1794-OE12 module, always refer to the official documentation provided by the manufacturer. The 1794-OE12 wiring diagram is an indispensable resource for this purpose.