Navigating the complexities of industrial automation often requires a clear understanding of essential components and their connections. The 1794 Tb3g Wiring Diagram is a crucial resource for anyone working with Allen-Bradley Flex I/O systems. This document provides the blueprint for connecting this specific terminal block to your control system, ensuring proper functionality and preventing costly errors. Having a solid grasp of the 1794 Tb3g Wiring Diagram is paramount for efficient installation and troubleshooting.

What is the 1794 Tb3g Wiring Diagram and How is it Used?

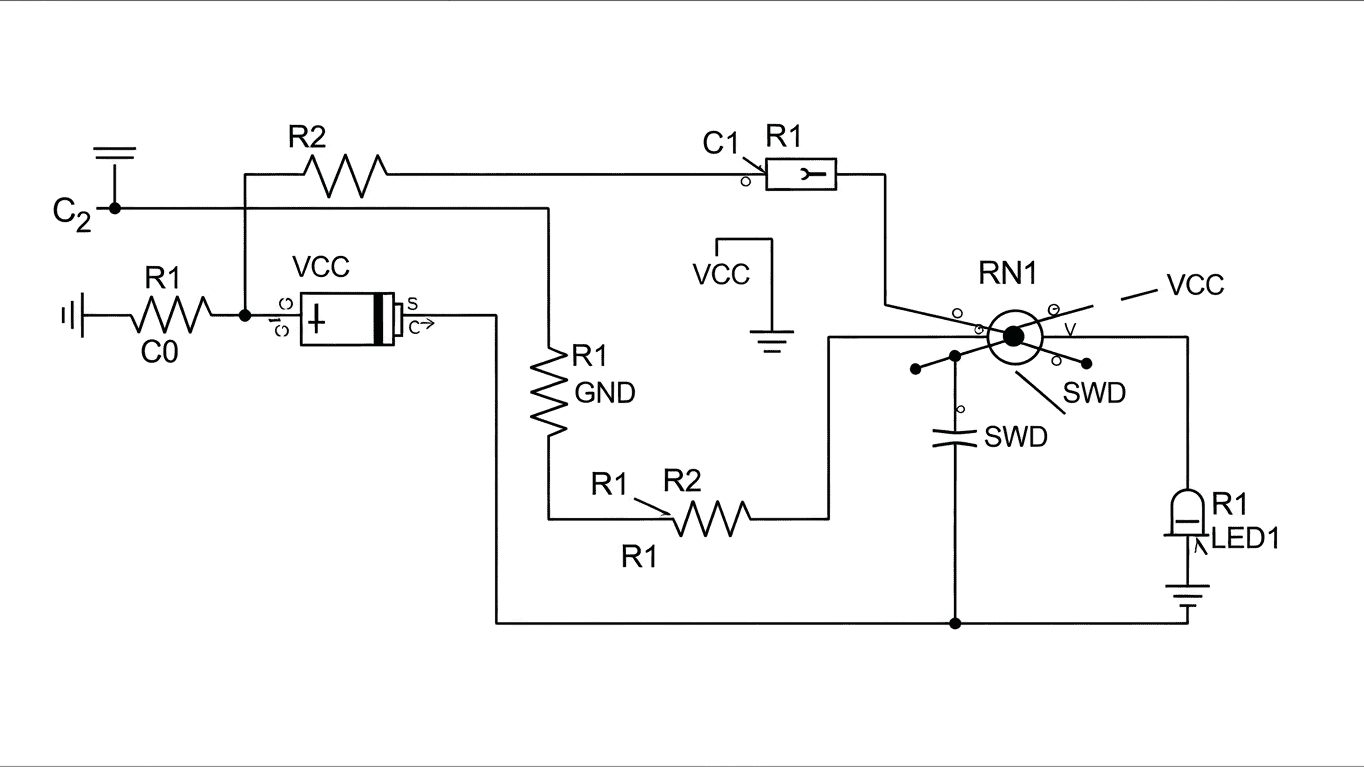

The 1794 Tb3g Wiring Diagram is a technical schematic that illustrates the pinout and terminal connections for the Allen-Bradley 1794-TB3G terminal block. This terminal block is commonly used as an interface between a Flex I/O digital output module and field wiring. It allows for the termination of discrete wiring from sensors, actuators, and other field devices to the digital output module of a PLC (Programmable Logic Controller). The diagram shows exactly which screw terminal corresponds to each pin on the Flex I/O module, and how the internal connections within the terminal block facilitate the signal flow. Properly interpreting and applying the 1794 Tb3g Wiring Diagram is essential for safe and reliable operation of automated systems.

These diagrams are indispensable tools during the installation and setup phases of an automation project. They serve as a guide for electricians and technicians to ensure that all field wiring is connected to the correct terminals on the 1794-TB3G. Without the wiring diagram, identifying the correct connection points would be a matter of guesswork, leading to potential miswiring, equipment damage, and system malfunctions. The diagram typically details the following:

- Terminal designations (e.g., L1, L2, COM, NO, NC, specific channel numbers).

- Internal connections within the terminal block.

- Wiring requirements for different types of output modules.

The practical application of the 1794 Tb3g Wiring Diagram can be seen in various industrial scenarios. For instance, when connecting a solenoid valve to a PLC output, the diagram ensures that the valve's power and control wires are connected to the appropriate terminals on the 1794-TB3G, which is then connected to the Flex I/O module. Consider a typical setup for a digital output module using the 1794-TB3G:

| Module Pin | Terminal Block Designation | Function |

|---|---|---|

| Output 0 | 1 | Common (COM) |

| Output 1 | 2 | Normally Open (NO) for Output 0 |

| Output 2 | 3 | Normally Closed (NC) for Output 0 |

| Output 3 | 4 | Common (COM) for Output 1 |

This table is a simplified example; a real 1794 Tb3g Wiring Diagram would be more detailed, showing all available terminals and their specific functions for the particular module it supports.

By diligently following the 1794 Tb3g Wiring Diagram, engineers and technicians can ensure that their automation systems are wired correctly from the start. This not only simplifies the installation process but also significantly reduces the time and effort required for troubleshooting in the future. It provides a clear roadmap for establishing reliable connections, which is the foundation of any successful industrial control system.

For detailed information and to access the specific schematics for your 1794-TB3G terminal block, please refer to the official documentation provided by the manufacturer. This resource is indispensable for accurate and safe wiring.